Yoneshima Felt Co.,Ltd.,

- 日本語

- English

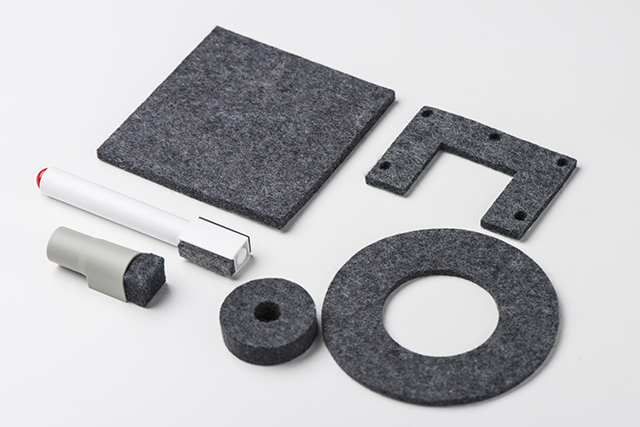

Pressed wool felt

Wool is commonly known for its heat retention, shock absorption, oil absorption, water absorption, workability, and soundproofing properties.

Suitable for a wide range of applications in automobiles, electrical equipment, stationery, and household-related materials.

- Spec

- Raw materials: 55–100% wool

Thickness: 1–30 mm Standard widths: 1,500W〜1,800W

Will manufacture to specification, including cutting, slitting, or punching as well as affixing pressure-sensitive adhesive backing.

1-mm thick colored felt is available in a wide variety of colors. Green felt is also available in thicknesses of 3- and 5-mm.

Heat resistance (working temperature): roughly 100°C

More about the heat resistance of felt

- feature

- Wool is commonly known for its heat retention, shock absorption, oil absorption, water absorption, workability, and soundproofing properties.

Suitable for a wide range of applications in automobiles, electrical equipment, stationery, and household-related materials.

- Production method

- Manufacturing flow chart

- Manufacturers

- AMBIC CO.,LTD. FUJI CORPORATION

- Standard product dimensions tables

- *We also have other product’s separate to those listed above.

JIS Standard

(Relevant product)Color Nikke Product No. Wool Standard Density Ambic Product No. Wool Standard Density R36W White K36 100% 0.36g/cm3 XW 100% 0.39g/cm3 R33W White K33 100% 0.33g/cm3 HW 100% 0.34g/cm3 R28W White 1100 100% 0.28g/cm3 FW 100% 0.28g/cm3 – White – – – AW 100% 0.25g/cm3 R25W1 White 1200 80% 0.25g/cm3 RW 80% 0.25g/cm3 R25W2 White 1300 60% 0.25g/cm3 CW 60% 0.25g/cm3 R25M Gray 2700 85% 0.25g/cm3 BM 80% 0.25g/cm3 R23M Gray 2800 80% 0.24g/cm3 GM 70% 0.23g/cm3 R19M Gray 2900 80% 0.20g/cm3 – – –

- Daily necessities

- Automotive applications

- Materials for factories

- Medicine

- Writing instruments

- Shock absorption, sound absorption, packing materials

- Dust proofing, dust collection

- Coating

- Polishing, burr removal

- Wool felt