Yoneshima Felt Co.,Ltd.,

- 日本語

- English

Processing Technology

Our Extensive Range of Processing Technologies

Although produced in batch rolls, our core product, pressed wool felt, is designed to be used as a component in other products. To that end, we have long used a range of machinery in our factories and those of our partners, such as shearing devices and steel cutting dies, to cut and press our felt to meet the needs of our clients. Over the years, we have built up extensive technological capabilities that can be used for other applications, including precision treatments to create highly functional and flexible materials. As a result, we at Yoneshima Felt have developed a number of products that have earned the top share of global markets in their respective categories.All of the processing technologies described below are offered to order, so do not hesitate to contact us to discuss your needs.

Ultrathin Slicing

We are able to thinly slice any materials along the thickest axis. With our original slicing technologies, foamed materials and other block-shaped items can be shaved as thin as 0.10 mm (tolerance ±0.02 mm). This is ideal for manufacturing the high-precision core materials of “sandwiched” functional composites. Our factory in Qingdao, China, is capable of prototyping and mass production.

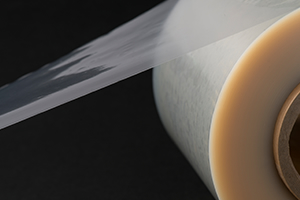

Ultrathin Laminating

Our ability to adhere multiple materials in layers is unsurpassed. Indeed, our original technologies enable us to provide clients with laminates of different materials measured in microns. These functional composites can then be used in a range of applications.

Our factory in Qingdao, China, is capable of prototyping and mass production.

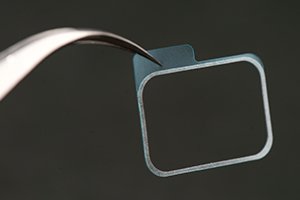

High-Precision Punching

From films and foamed materials to double-sided tape and other multi-material laminates, we are able to punch a range of items to a high degree of precision with widths as small as 0.45mm (tolerance ±0.08mm).

(Size range depends on thickness and hardness of products.)

Our factory in Qingdao, China, is capable of prototyping and mass production.

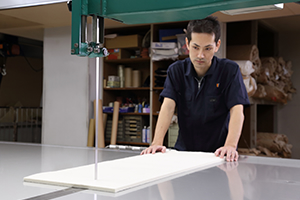

Vertical Cutting

We are able to cut natural wool and synthetic felt as well as foamed products from the roll to any size you require using our vertical cutting machinery. By the meter or any other size up to 2,000 mm x 2,000 mm.

Slitting

We are able to cut natural wool and synthetic felt into tape strips of any size you require. From as narrow as 10 mm to as wide as 900 mm, we can produce seamless tape as long as the original felt roll.

(Size range depends on thickness and hardness of products.)

Adhesion

We are able to apply adhesive substances to your felt and foamed products. Adhesives are normally applied without a base material, but base material containing washi paper is also available to suit product requirements.

Naturally, products can be cut to size, slit, die-cut, and punched after the application of adhesives, and we can even half-cut products to allow easier peeling of base paper.

Automatic Cutting

We are able to cut felt and foamed products to size automatically using our range of machinery, and can punch products into rings or other shapes using die-cutting. Automatic cutting offers better size consistency and shorter turnaround times even for large production lots.

Quick Prototyping

Using CAD, plotting equipment, and laser devices, we are able to provide clients with prototype products quickly. Contact us now to discuss your prototyping needs.